Shanghai Non-ferrous Metals P.D. Development Trade Co.,Ltd.

| About us | 1.High-Temperature Alloy The aircraft gas turbine engine market has traditionally been the major user of HASTELLOY and HAYNES high-temperature alloys. Here the story has been one of incremental growth as each major advance in engine performance capitalizes on the development of newer and more efficient materials of construction. MULTIMETâ alloy was the first signifcant wrought HAYNES high-temperature alloy offered to the aviation industry. HASTELLOY X alloy, the next major development is still the 'workhorse' of the industry. HAYNES 188 alloy later offered engine designers a much higher temperature advantage. The newest HAYNES 230 alloy is gaining increased use because of its unexcelled combination of high-temperature strength and oxidation resistance plus improved thermal stability. Also, the newer HAYNES 242 alloy, show great promise for aircraft engine seal rings, containment rings, duct segment, casings and fasteners. 2.Corrosion-Resistant Alloys The Corrosion-Resistant HASTELLOY alloys have become widely used by the chemical processing industries. However, the need for reliable performance has lead to their acceptance and growth in the areas of energy, health and environmental, oil and gas, pharmaceutical andflue gas desulfurization industries. The attributes of HASTELLOY alloys include high resistance to uniform attack, outstanding localized corrosion resistance, excellent stress corrosion cracking resistance, and ease of welding and fabrication. The most versatile of the HASTELLOY alloys are the 'C-type' alloys. C-2000 alloy combines outstanding resistance to oxidizing media with superior resistance to reducing environmetns and represents a true performance breakthrough for chemical process equipment application. C-22 alloy is particularly resistant ot pitting and crevice corrosion; It has been used extensively to protect against the most corrosive FGD systems, and the most sophisticated pharmaceutical reaction vessels. G-30 alloy was designed specifically to resist commercial phosphoric acid. As such, it has been very successful as heat exchanger tubing and for other process components in the fertilizer industry. By virtue of its high chromium content, it is also the premier choice for strong oxidizing solutions and mixed acid pickling services. G-50 alloy is a tubing material developed for deep sour gas environments. It is intended for use in the cold-worked condition and is very resistant to hydrogen embrittlement. B-3 alloy is the newest of the 'B-type' alloys. The alloy possesses outstanding resistance to reducing acids, such as hydrochloric acid and sulfuric acid. The advantages of B-3 alloy over previous B-family alloys are enhanced thermal stability and improved fabrication characteristics. D-205 alloy has been successfully used in plate heat exchangers exposed to hot concentrated sulfuric acid. It exhibits several advantages over the high-silicon stainless steels, including enhanced resistance to pitting corrosion in chloride-bearing media. 3.Corrosion-Wear Alloys Wear-resistant alloys were the forte of Haynes from the inception of the STELLITE alloys in the 1910's. Recent developments in the 1990's lead to further improvement with the new corrosion-wear resistant ULTIMET alloy. ULTIMET alloy exhibits a unique blend of properties. Like other cobalt-base alloys, it possesses exceptional resistance to galling, cavitation erosion, slurry erosion, and hot abrasion. It is also very corrosion-resistant, ductile, and easily welded and fabricated. It is becoming a standard material ofr valve, pump, and nozzle manufacturers. |

|---|---|

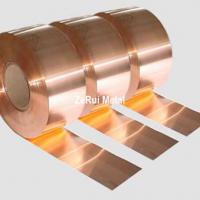

| Industry Focus | Non-ferrous Metal Products, Non-ferrous Metal Alloy, Non-ferrous Metal |

| Business Type | Trading Company |

| No. of Employees | 101 - 500 People |

| Annual Sales Range(USD) | US$1 Million - US$2.5 Million |