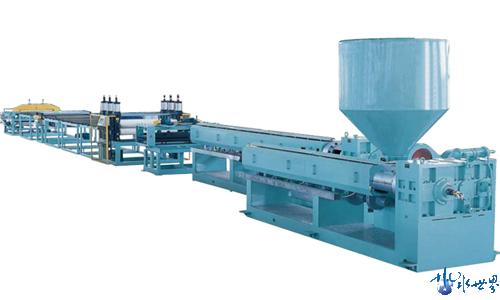

Foamed Board and Sheet Production Line - SJ Specificaton & Trade Terms

| Model | SJ |

|---|

| Place Of Origin | China |

|---|

| Packaging | as your customers' requirment |

|---|

| Brand | Keshengda Machine |

|---|

| Certifications | ISO9001 |

|---|

| Price Term | EX-Work |

|---|

| Payment Term | T/T |

|---|

| Supply Ability | 100 |

|---|

| Minimum Order | 1 pcs |

|---|

| Loading Ports | Qingdao |

|---|

| Delivery Time | 40-60 days |

|---|

XPS Foamed Board Production Line/ Foamed Board Production Line/ XPS Board Extrusion Line:

XPS foamed polystyrene board (referred to as XPS) has a perfect closing-cell honeycomb structure, and is recognized as one of the best insulation materials in market. EPS is materialized by recycled polystyrene board and reproduction foam particle which are processed by extrusion, foaming and shape forming from die heads. haul-off, cutting to accomplish product manufacture process. It is lower than other kinds of heath preservation board materials in density, water-absorption rate, heat conductivity factor, steam permeability factor and so on. Therefore, it has features of good strength and light weight; it is air proof, corrosion resistant, anti-aging, low pricing and etc. The material is widely applied in roof insulation system; refrigerating store room, barracks, granary, and civil architecture wall insulation; airport runway, squares and other ground construction fields; road, railway civil engineering; the insulation separation system in departments, office buildings, factories and other constructions .