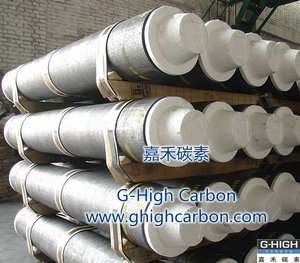

Graphite Electrode - GH-GE Specificaton & Trade Terms

| Model | GH-GE |

|---|

| Place Of Origin | PANJIN,CHINA |

|---|

| Packaging | crate |

|---|

| Brand | G-High |

|---|

| Price Term | FOB,CIF,CFR |

|---|

| Payment Term | T/T,L/C,DP |

|---|

| Supply Ability | 150,000 tons per year |

|---|

| Minimum Order | 20 tons |

|---|

| Loading Ports | Dalian Port, Tianjin Port |

|---|

G-High Graphite Electrodes are made from Petroleum Coke and Needle Coke, using Coal Tar Pitch as agglutinant, produced through the process of calcining, mixing, kneading, compressing, roasting, graphitization and machining, etc.

G-High Graphite Electrodes have the properties of superior electric conductivity and chemical stability, high mechanical strength, less impurity, seismic performance in high temperature. G-High Graphite Electrodes are mainly used for steel-making in electric furnaces, mineral hot furnaces and electric resistance furnaces.

Graphite Electrodes conduct electric current into the furnace. Electric current produces arc in the smelting district, when the temperature increases to about 2000°C, smelting begins. Our series of Graphite Electrodes are applicable to the common furnaces and high power furnaces with high voltage and short arc. G-High Graphite Electrodes are classified into three classes.

NP Graphite Electrodes: mainly used in common power electric ovens for smelting steel, smelting silicon and smelting yellow phosphorus;

HP Graphite Electrodes: mainly used in high power electric ovens for smelting steel;

UHP Graphite Electrodes: mainly used in ultra high power electric ovens for smelting steel.

For more information about the specifications of graphite electrode, please kindly visit our web.