extruder parallel twin screw barrel - 35/ 35 ~ 250/ 250 Specificaton & Trade Terms

| Model | 35/ 35 ~ 250/ 250 |

|---|

| Place Of Origin | China |

|---|

| Packaging | Wooden case |

|---|

| Brand | Sheen |

|---|

| Gurantee | We can gurantee delievey time and production |

|---|

| Certifications | ISO 9001:2008 |

|---|

| Price Term | FOB |

|---|

| Payment Term | T/T |

|---|

| Supply Ability | 300 sets per month |

|---|

| Minimum Order | 1 set |

|---|

| Loading Ports | Ningbo |

|---|

| Delivery Time | 20 working days upon recepit of 30% deposit |

|---|

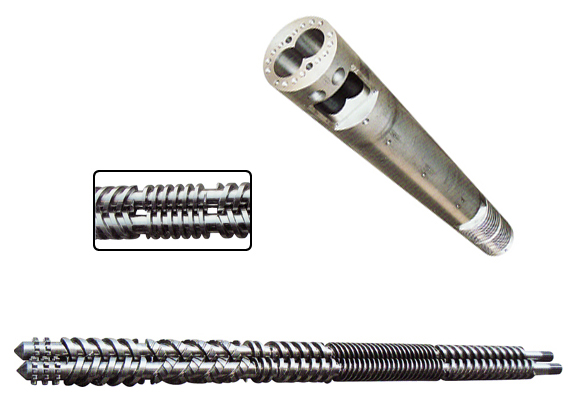

Parallel twin screw&barrel

Processing range:Φ35/ Φ 35 ~ Φ 250/ Φ 250

Material:38CrMoALA,SKD11,SKD61,Stainless Steel, SACM645,SCM440

Surface Treatment: PTA, Vacuum heat treatment, Gas nitrided , Hard chrome plating, phorphor nickel alloy plating.

Technical Details:

☆Nitriding Treatment: 120 Hours

☆Depth of Nitrided Layer: 0.5-0.8 mm

☆Hardness of Nitrided Layer: 900-1020Hv (HRC56°-65°)

☆Regulating rigidity:HB260-290

☆Fragility of Nitration:≤Two class

☆Roughness of the surface:Ra0.4um

☆Linearity of the screw: ≤0.015mm

☆Linear axis limit: ≤0.02mm

:Material Application:

☆General Plastics: ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc

☆PA + GF(Glass Fiber)

☆Flame-resistant Reinforced Plastics

☆Modified Engineering Plastics

☆All kinds of Mixed Recycled Material(in Scrap or Granule),etc

Compressing rate of screw can be designed according to different raw materials and products

Twin screw and barrel made: CINCINNATI, BATTENFELD, KRUSSMAFFEI, BAUSANO and AMUT model spares

Choosing us is your right decision,we can do:

1:To provide users with mapping,professional manufacture screw,barrel and accessories.

2:we can supply appropriate screw cylinder according to the features of products and the demands of customers.

3:Best material,according to production process.

4: We can guarantee delivery time.