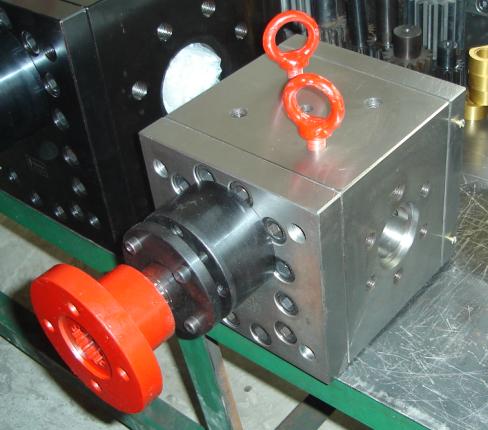

extrusion melt pump - ZB Specificaton & Trade Terms

| Model | ZB |

|---|

| Place Of Origin | China |

|---|

| Price Term | EX-Work |

|---|

| Payment Term | T/T |

|---|

Although the extrusion process works without the use of a gear pump, adding a pump at the end of the extruder offers several advantages.

The main advantage is the consistency and quality of the output.

The gear pump, also called a melt pump, is a positive displacement device so the output is a consistent predictable volume per revolution.

The gear pump is made for pumping at high pressure; therefore, it is more efficient than the extruder at building the pressure required to overcome the back pressure of the system (die and screenchanger).

The volumetric efficiency of the melt pump is 98 to 99 percent, whereas the extruder's efficiency is only about 45 percent. This means that adding a gear pump to the extruder will usually result in lower total power consumption.

By taking the pressure building away from the extruder, wear is also reduced on the components of the very expensive extruder.

Extrusions pump systems, including drives and controls, usually pay for themselves in a few months by reduced scrap and raising throughputs.

Pumps for molten polymer are highly engineered positive displacement devices.